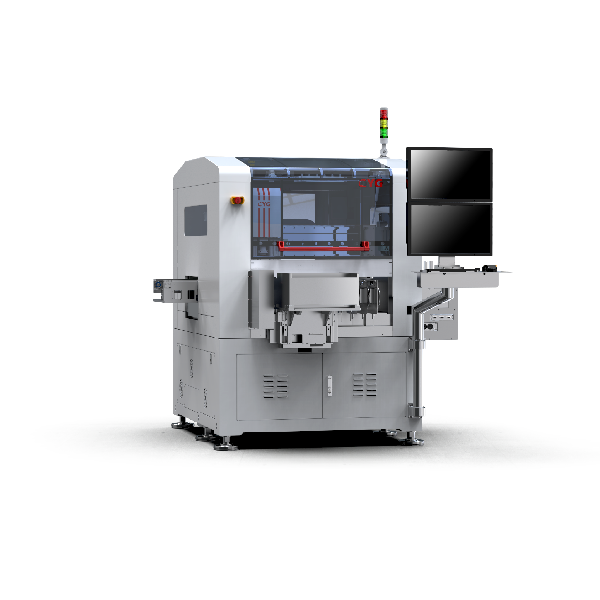

| Project | Specification Description |

| Mounting Method | Solder preform, Solder paste |

| Placement Accuracy | X/Y ±10μm(3σ、based on calibration block verification accuracy) |

| Cycle Time | 1s(pickup and placement time), UPH depends on product process |

| Material Size | Chip size 2x2~20x20mm,chip thickness>0.05 DBC size : 30~50mm(W),thickness 0.9~1.2mm |

| Bond Force | 30-300g |

| Solder Film CuttingAccuracy | ±0.1mm |

| Wafer Size | 6~12 inch |

| Product Loading Function | Wafer Frame、Waffle Pack Tray、vibrating feeder、parts feeder、Metal Frame 、Magazine… etc. |

| Available Materials | FRD、IGBT chip、NTC、Solder Film、Metal Frame 、DBC、Carrier、Space… etc. |

| Carrier size | Rail width adjustable : 85mm ~ 332mm |

| Bonding Head Rotation Angle | 360° |

| Pick up Nozzle | Auto-change, 12 sets different type |

| Ejector | Auto-change, 4 sets different type |

| Others | Optional modules include glue dispensing module, scanning module (including wafer, DBC, fixtures, tape) |

| Dimension | 1200x1500x2200 mm(excluding the protruding part of the equipment body) 2000x1900x2200 mm (including the protruding part of the front and rear docking tracks and basket lifting table) |

High Precision Multi-heads Bonder

Suitable for such as IGBT, sensor, memory chip, laser diode and other IC chip bonding processes. Dual-liner motor driving gantry structure with multi-head and flying vision for the mounting process for different chips, solder pieces, graphite frames, substrate, DBC, fixtures, and other devices.

Contact