| Project | Specification Description |

| Placement Accuracy | X/Y ±25μm(3σ,verified based on calibration block),θ±1゜ |

| Cycle Time | 1.5s( UPH depended on product process and quantity ) |

Product Size | chip size 1.5x1.5~15x15 mm, chip thickness 0.07-3mm |

| Bond Force | 20-300g |

| Product Loading Methods | Waffle pack Tray (wafer optional) |

| Bond Head Rotation Range | 360° |

| Dimension | 1450(L)x1200(W)x2000(H) mm |

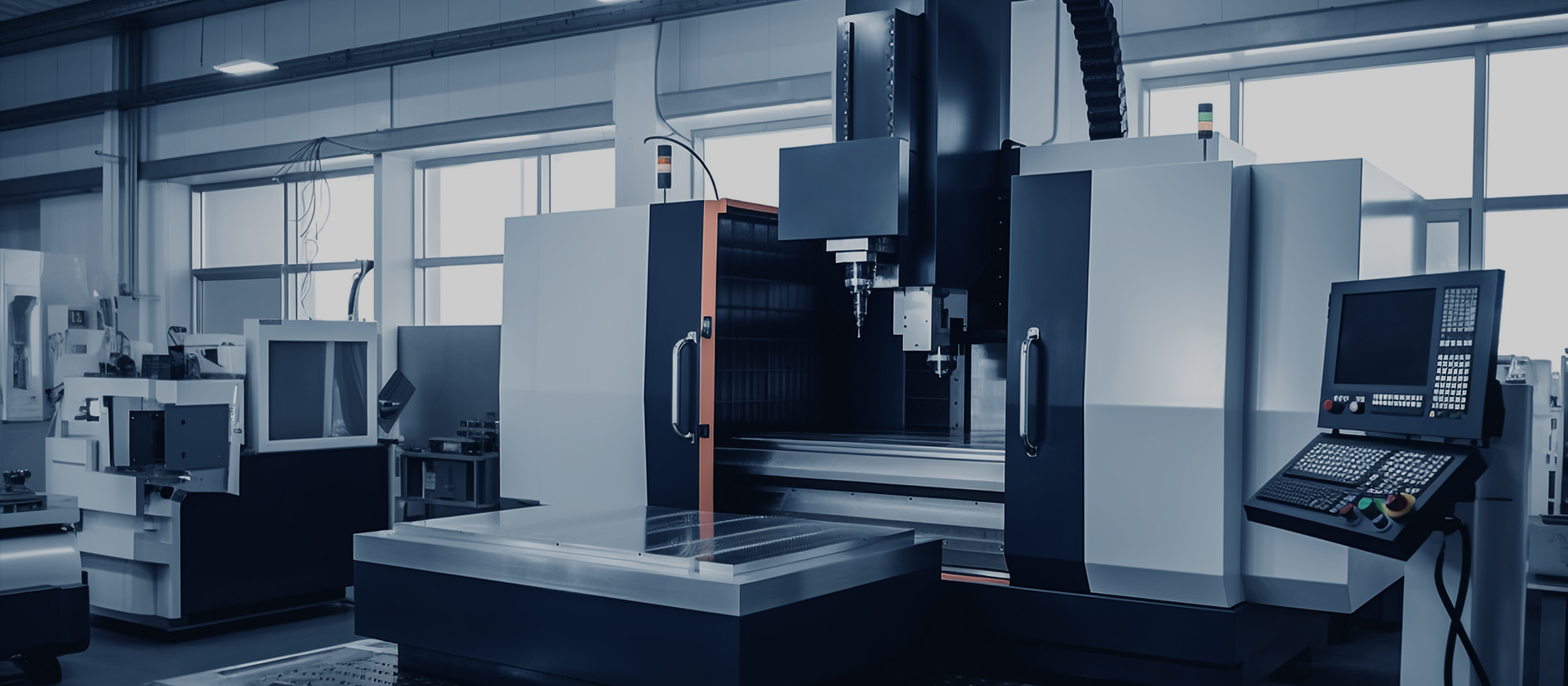

Chip Inspection and Sorting Machine

Equipment can be applied to IC chip defect inspection and sorting. It suitable for picking and sorting of various semiconductor chips such as IGBT, sensor, memory chip, laser diode, etc. The process is the chips are picked up from the tray or wafer, performed top side or side-wall inspection and then placed into the dedicated tray.

Contact