| Project | Specification Description |

UPH | Econo series <20 s/module, HPD/HP1 < 30 s/module |

DBC mounting Accuracy | 0.05mm |

| Bar Code Reading error rate | <0.01% |

| Repeat Positioning Accuracy | <0.05mm |

CCD Positioning Accuracy | 0.014mm |

| Servo Press | Pressing stroke : 200mm;Pressing force : 3T; Pressing speed:0-200mm/s |

| Glue Mixing Method | Static mixing tube |

Equipment Operating Noise | Continuous noise ≤70dB(A) (measured at a distance of 1.5m from the equipment) |

| Equipment Stability and Reliability | MTBF≥168h, MTTR≤20mins, MTBA≥3h, MTTA≤3mins |

| Failure Rate | <2% |

| Cmk | >1.67 |

| Supporting Functions | Operation authority management, communication with the machine and compliance with SMEMA standards, interface types should meet Secs/Gem and other types, to achieve product traceability requirements. |

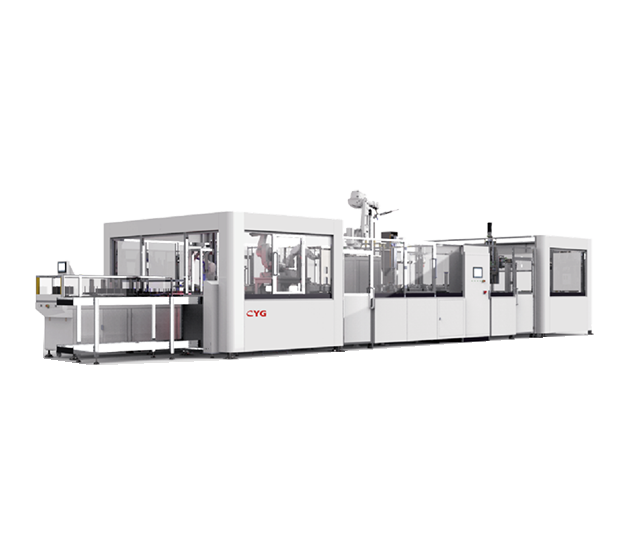

IGBT Automatic Assembly Line

Suitable for ECONO series, HPD packaging, it mainly including DBC mounting, reflow soldering, positioning frame disassembly, cleaning, X-Ray, housing glue dispensing, room temperature aging cabinet bonding and cleaning, vacuum potting, high temperature curing furnace, and housing packaging and unloading.

Contact