| Project | Specification Description |

UPH | Econo Series <20 s/module |

| DBC mounting Accuracy | 0.05mm |

| Bar Code Reading error rate | <0.01% |

| Repeat Positioning Accuracy | <0.05mm |

CCD Positioning Accuracy | 0.014mm |

| Force Control | +/0.5N |

| Displacement Control | +/-0.01mm |

Equipment Operating Noise | Continuous noise ≤70dB(A) (measured at a distance of 1.5m from the equipment) |

| Equipment Stability and Reliability | MTBF≥168h, MTTR≤20mins, MTBA≥3h, MTTA≤3 mins |

| Failure Rate | <2% |

| Cmk | >1.67 |

| Supporting Functions | Operation authority management, communication with the machine and compliance with SMEMA standards, interface types should meet Secs/Gem and other types, to achieve product traceability requirements. |

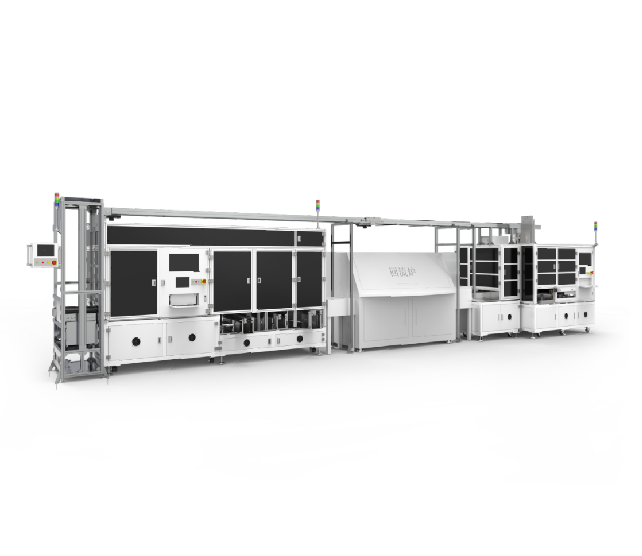

Vacuum Reflow Automatic Line

Suitable for ECONO series, ECONO PACK2, ECONO PACK3 & ECONO DUAL3 packages. It mainly includes spot soldering fluxes, online cutting and feeding of solder preform, vacuum reflow soldering of DBC patches, dismantling of position frames, and cleaning of reflow soldering carriers and position frames.

Contact