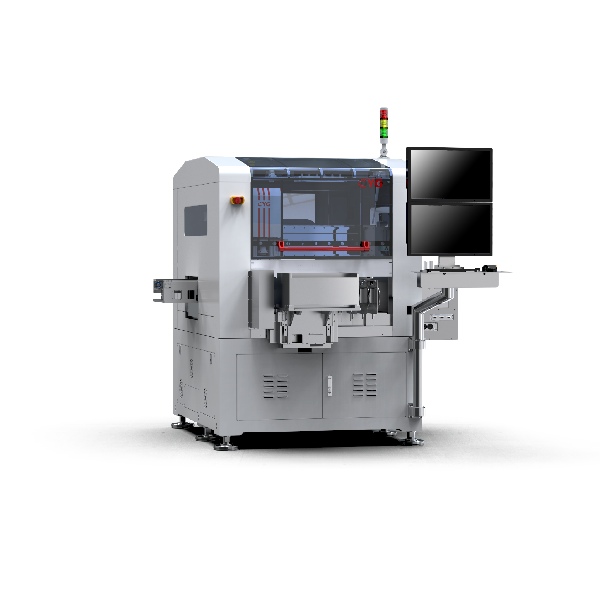

| Project | Specification Description |

SMT method | Solder pads, solder paste |

Chip SMT accuracy | X/Y ± 10 μ m (3 σ, based on calibration block verification accuracy) |

| Production speed | CT 1s (pick-up and drop time) UPH depends on the product process and quantity |

| Product size | Chip size 1.5 * 1.5~20 * 20mm, chip thickness 0.05~0.2mm DBC size supports width 30~50mm, thickness 0.9~1.2mm |

Range of loading and unloading force control | 30-300g |

| Welding blade cutting accuracy | ±0.1mm |

Patch size | 8-inch (6-inch compatible) |

| Support product delivery methods | Wafer or waffle box stacking materials, vibration discs, Feida, Tray and frame stacking, Magazine, etc . FRD, IGBT chip, NTC and its solder pads, frame DBC、 Tooling, Space, etc |

| Support product types | FRD, IGBT chip, NTC and its solder pads, frame DBC、 Tooling, Space, etc |

| Compatible tray size | The track width can be adjusted from 85mm to 332mm |

| Bangtou rotation angle | 360 |

| Automatically change the number of suction nozzles | 12 groups |

Automatic replacement of ejector pin module | 3 groups |

| Other | Optional modules include spray adhesive fixed patch module, scanning function module (including wafer, DBC, tooling, and tape), and dispensing function module |

| Equipment size | 1200 * 1500 * 2200mm (excluding protruding equipment body) 2000 * 1900 * 2200mm (including front and rear docking tracks and protruding equipment parts of flower basket lifting platform) |

Pre-sinter Bonder

This equipment is suitable for high precision and high temperature prefixed crystal of SiC chips Support the pressure sinter paste or the pressure sinter film process

Contact